Hydrogen Gas Generator

Applications :

- GC-FID & TCD

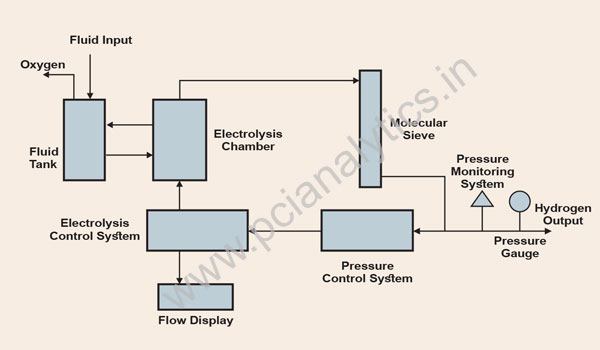

- Hydrogen is produced in the PGH Series Hydrogen Generators by the most advanced electrolytic membrane technology.

- The application of voltage across the electrolyte results in hydrolysis, breaking down the water molecule into hydrogen and oxygen gas, which are separated by the gas permeable membrane.

- Once separated, the hydrogen gas goes through a series of purification and moisture removal systems to achieve the desired level of purity while the oxygen gas is being discharged into the atmosphere.

- Electrolytic membrane technology has its advantages over alternative hydrogen generating techniques as it is clean, requires less maintenance and there is no need to store chemicals to maintain operation.

- Only pure double distilled water (initially some KOH), is required to provide trouble free long term operation.

- Membrane separation is also less time consuming as only water is needed for routine maintenance.

- Another model with no acid and alkaline solution (KOH & NaoH) is also available.

- Seperate model of Hydrogen Generator (without KOH) with pressure upto 7 bar also available.

Salient Features :

- Low working pressure & continuous UHP grade flow (99.999%)

- Generate hydrogen with PEM technology

- Generator has in built pressure switch which shuts off the generator in case of Over pressure built up.

- Sleep mode in case no use of H2 gas.

- Hydrogen leak detection facility inside the generator. (Optional)

- Any leak detected will shut the system and hyrogen production is halted. (Optional)

- Low Water Level Alarm (Optional)

Technical Specification :

| PGH-300 | PGH-500 | PGH-1000 | |

| Max Hydrogen Flowrate | 300 ml/min | 500 ml/min | 1000 ml/min |

| Delivery Pressure | 0-60 psig (0-0.4 Mpa) | ||

| % Purity | 99.999% | ||

| Power | 198-242V (AC); 50Hz,1 Phase | ||

| Min/max Temperature | 5-40°C | ||

| Suitable Environment | non-corrosive and dust-free | ||

| Dimensions | 420 X 210 X 350mm (LXWXH) | ||

| Weight | 20 kg (approx) | ||

| Fluid Tank Capacity | 3 Ltr. | ||

| Gas Outlet Port | 1/8" OD | ||

* Higher capacity model also available like 2 LPM & 3 LPM